Understanding the Semiconductor Ecosystem: Part 2- From Back-End Processes to Industry Specialized

In Part 1, we explored the key players at the front-end of the semiconductor journey, those who design and manufacture chips. But what happens after a chip is designed and produced? That’s where the follow-up processes come into play.

These back-end processes are just as critical as front-end design and fabrication. They include cutting, packaging, and testing the chips before they are embedded into the electronic devices we use every day. Let’s take a closer look at who takes charge of these final steps.

The Role of OSATs in the Back-End

Once a foundry completes the production of semiconductor wafers, the next stage is handled by Outsourced Semiconductor Assembly and Test companies (OSATs). As the name suggests, these companies specialize in assembling chips into packages and rigorously testing them to ensure quality and reliability.

Why the Industry Became More Specialized

Semiconductors are critical components in high-value and high-performance products, making reliability and precision at every stage essential.

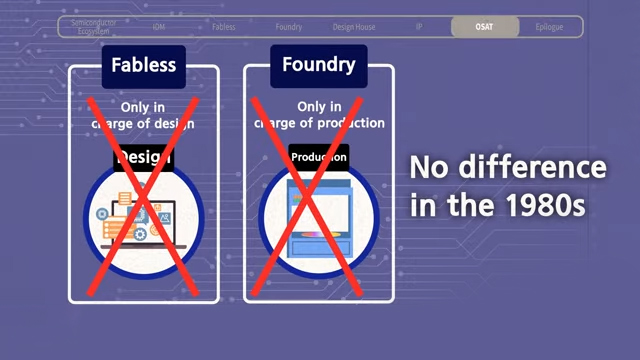

In the early days of the semiconductor industry, until the 1980s, there was little distinction between players. The first generation of system semiconductor companies typically handled everything in-house, from design to production and packaging, which made the entry barrier incredibly high.

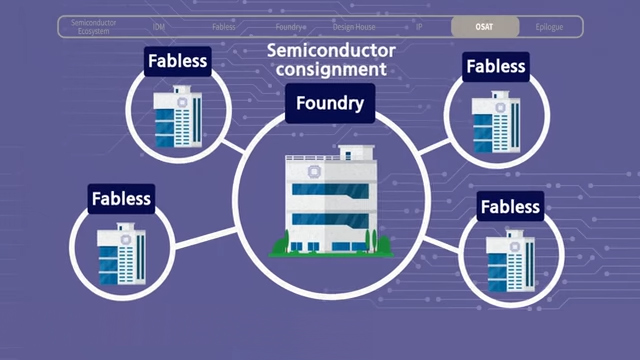

But this began to change with the emergence of foundries. By offering dedicated manufacturing services, foundries enabled the growth of fabless companies that could focus solely on design. This separation of roles pave the way for greater innovation and competition, ultimately accelerating the pace of semiconductor development.

As the industry continued to evolve, further specialization became necessary. From IP providers to design houses, foundries, and OSATs, each player focused on a specific stage of the process.

The Full Semiconductor Value Chain at a Glance

Across both parts of this series, we’ve explored the full scope of the semiconductor ecosystem. To summarize, here’s how the major players come together to bring chips from concept to completion:

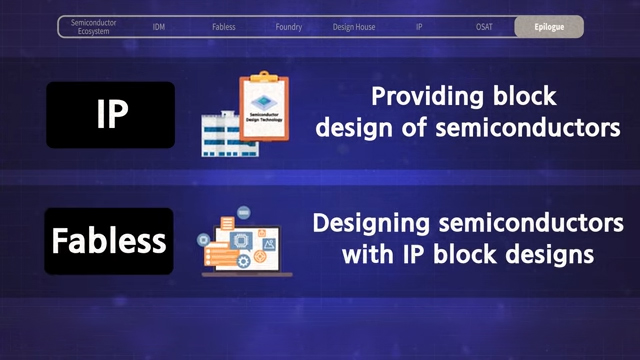

- IP Companies provide reusable semiconductor design blocks (IP).

- Fabless Companies design chips, often using licensed IP and outsourcing manufacturing.

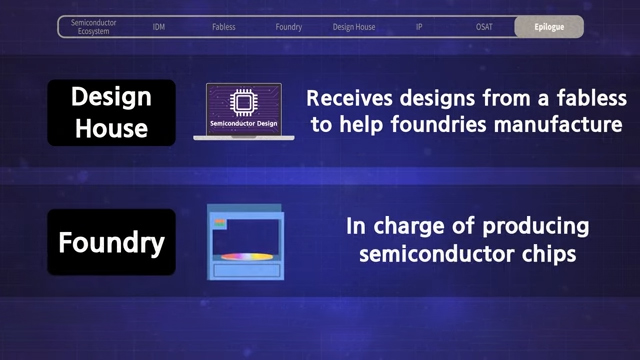

- Design Houses refine and optimize designs to meet the technical specifications of foundries.

- Foundries manufacture chips using advanced fabrication technologies.

- OSATs packag chips, and conduct quality assurance test.

Each company plays a specialized role at a different stage of the value chain. Together, they form a dynamic and collaborative ecosystem, built on trust, technical expertise, and constant innovation.

From start to finish, the semiconductor journey is defined bycomplexity, precision, and collaboration. As we’ve seen in this two-part series, it takes a tightly woven network of specialized players to transform abstract designs into the foundational components of our digital world.